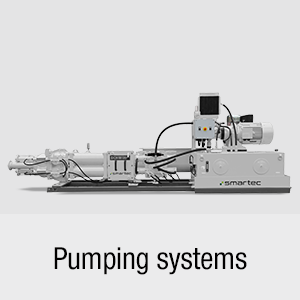

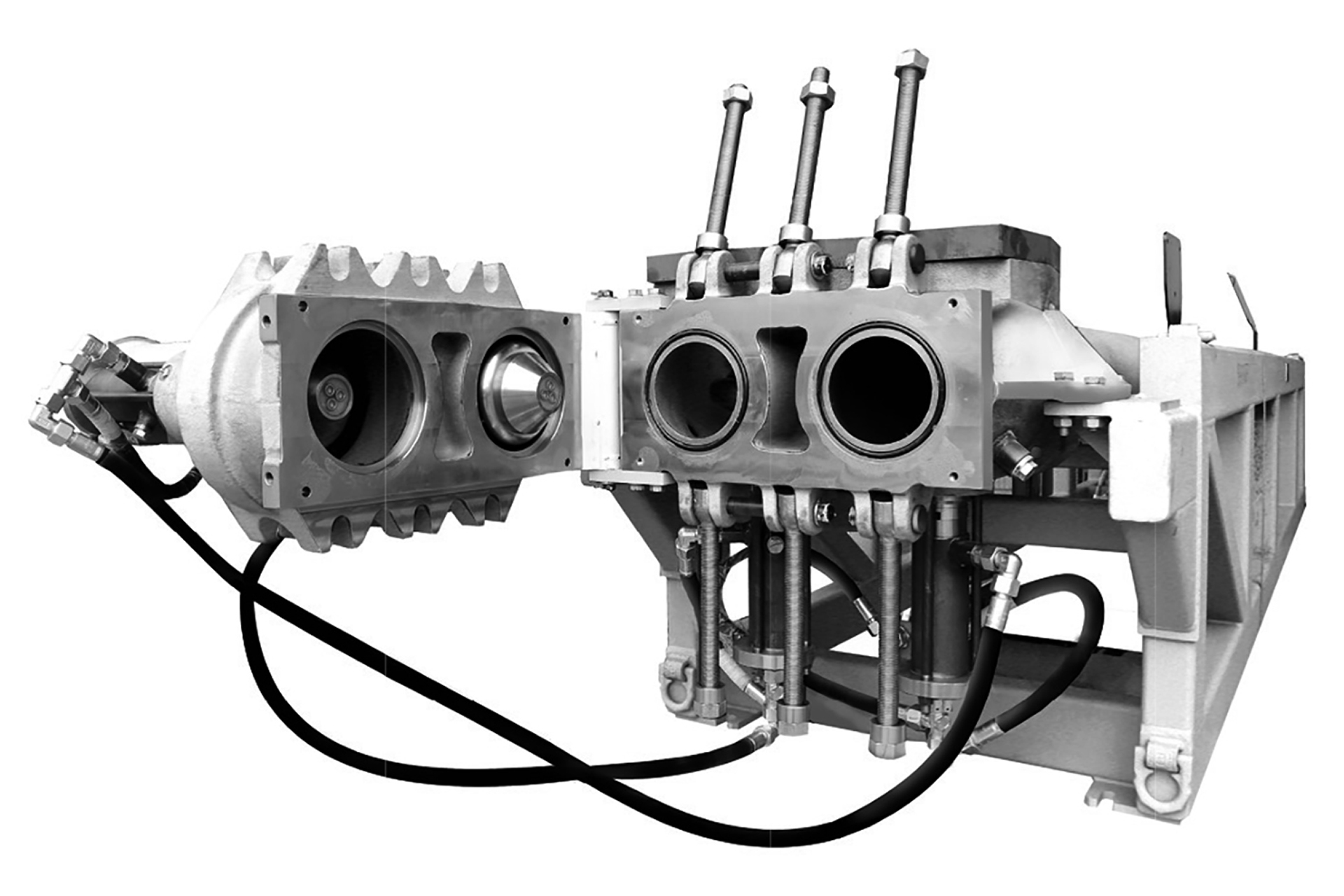

The Wupperverband, based in Wuppertal, operates 14 reservoirs, eleven sewage treatment plants, a sludge incineration plant as well as flood retention basins and stormwater tanks in the catchment area of the river Wupper. At the Buchenhofen site in Wuppertal/Germany, a high-performance wastewater treatment plant ensures clean conditions. The sewage sludge that inevitably arises during the treatment of wastewater in Buchenhofen and surrounding sewage treatment plants is dried and incinerated in the adjacent incineration plant in an environmentally friendly manner. A new, turnkey pump system from SCHWING has recently been installed for transporting the sewage sludge and feeding the incineration furnaces. This system comprises a sludge pump, a double screw feeder, a drive unit and a lubrication dosing system. The existing sewage sludge receiving silo with a capacity of around 35 m³ was integrated into the plant. The silo is connected to the two alternately operated incinerators via a 115 m long insulated and stainless steel lined conveyor line, which was also supplied and installed by SCHWING as part of the order. The automatic lubrication dosing system minimizes frictional resistance by adding water in a metered amount at the beginning of the conveying line, thus reducing the energy required to convey the medium. The task of the double screw feeder, which was installed under the existing receiving silo, is to homogenize the medium to be conveyed, in this case sewage sludge, and to build up a pre-pressurization pressure for continuous and adjustable feeding of the medium to the high density solids pump. This increases the filling level of the delivery cylinders so that a high output rate is guaranteed even with highly viscous media. The sludge pump KSP 10 HDV with poppet valve system (STVE) achieves a maximum output of 7 m³ per hour and requires only 15 strokes per minute. The hydraulic unit for driving the high density solids pump and the double screw feeder was installed behind the existing receiving silo and is driven by a highly efficient electric motor with a power of 55 kW. The entire pump system is connected to the central control room in the main building with the incineration plant and is monitored from there. For maintenance of the sludge pump's poppet valves, the pressure housing can be simply folded to the side after loosening the screw connection. Afterwards the valve disc and the valve seat can be turned or replaced if necessary, depending on the degree of wear. The low maintenance requirements of the SCHWING poppet valve system and the easy replacement of wearing parts ensure low operating and maintenance costs. After commissioning the new plant, the Wupperverband now uses a total of 17 high sludge pump systems from SCHWING at the Buchenhofen site in Wuppertal. The Wupperverband is celebrating its 90th birthday this year. Then, as now, the association is centrally responsible for the water management tasks of the towns, communities, districts, water supply companies, industry and trade in the Wupper region. It is responsible for the maintenance of around 2,000 kilometres of rivers and streams.